Barnes began making the tenoning machine about 1878. Over the years, there were several slightly different versions until it was discontinued in the early 1900’s. It is estimated that just over 3000 of these were made.

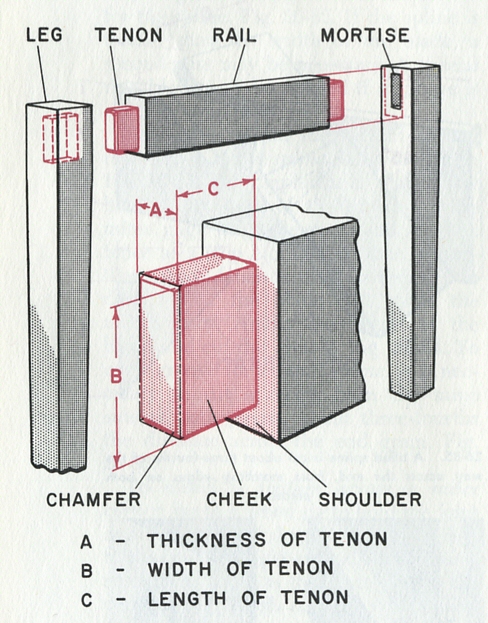

To cut the actual tenon, you took the rack handle, which through a rack and pinion gear set then moved two cutters back and forth over the wood to shave off a little bit at the time. (See catalog cuts below for more details) Once the top and bottom were cut, you had to rotate the work piece 90 degrees and then cut the sides. This had to take time as you were basically using a hand plane to cut the tenon as compared to a saw and perhaps a chisel to clean it up.

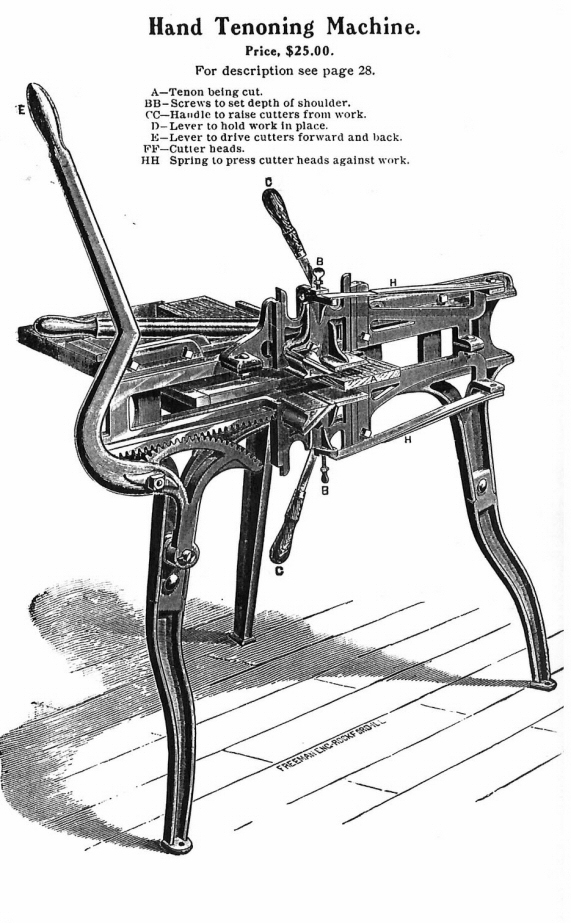

Front view of the later model.

A view from the top showing the hold down stick. Note the part of the frame with holes where the very end slips into.

Here is a close up shot showing the frame with the holes where the operator would insert the tip end of the hold down. Note the “tip end” as a part of the cast iron end. The hold down stick is laying on the table. You can also see the gold high lighting, the pin striping and the faded Barnes gray base color in this shot.

The tenoning machine appears to have never been very popular. It worked by placing the piece of wood to have the tenon on a rather short table and holding it in place with sort of a “hold down stick”. To adjust to the thickness of the wood, the end of the hold down stick had to be placed in the proper hole on the frame. Compare this to cutting one with a handsaw.

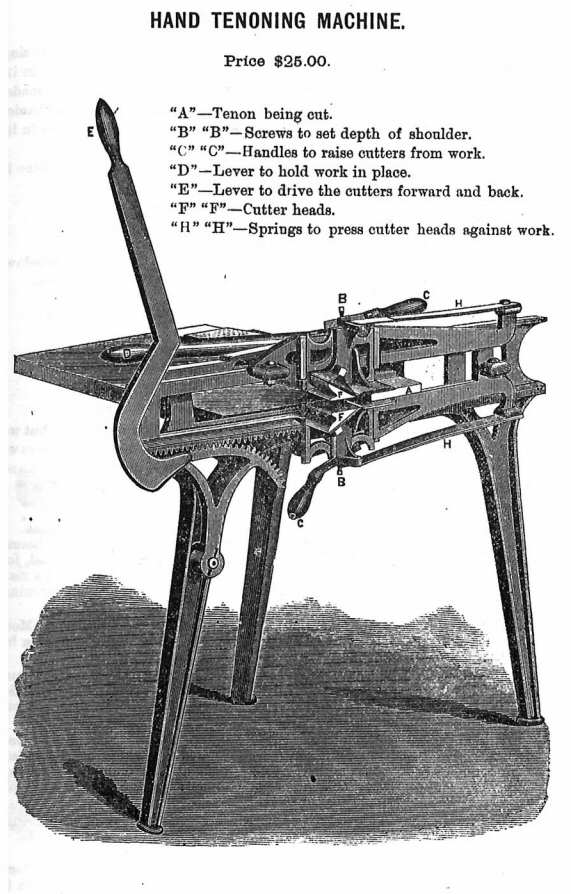

These catalog pages from an early 1880’s catalog show the various parts labeled. Note the straight legs.

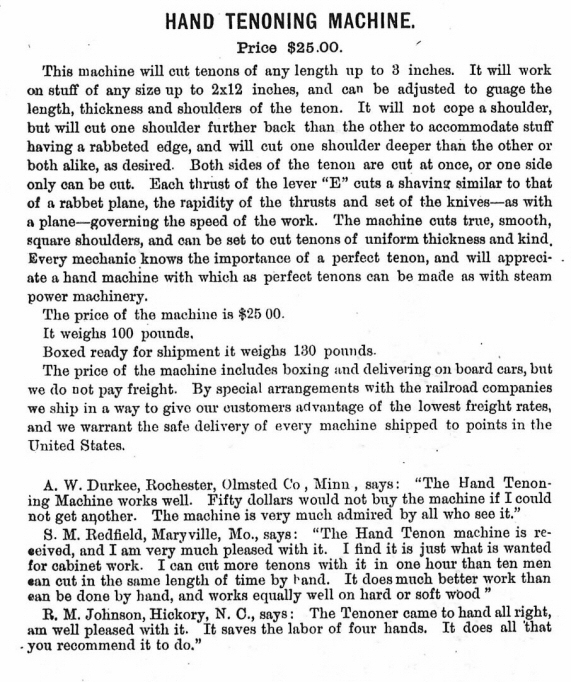

Here is what that catalog said about the machine. Nothing like a good testimonial to help sell the product.

This catalog page shows the later and last version of the tenoning machine from a 1901 catalog. By having the front two legs curving out, this gave the machine more stability. With the relatively small size and weight of the machine, this would appear to be very important.

From what we can tell, it does not appear that any other company made a hand operated tenoning machine. Perhaps Barnes felt they needed a tenoning machine to go along with their mortising machine but who knows!