Note!! Because the #7 was the beginning of the W F & Barnes Company, more background material is included for this machine.

The Barnes #7 Scroll Saw, also initially referred to as the Large Saw, was the genesis of the foot powered machine business for what ultimately became known as the W F and John Barnes Co of Rockford, IL (Barnes as it is commonly referred to, was arguably the largest and most successful manufacturer of commercial grade foot powered machinery in the world.)

In addition to being an inventor with a number of patents related to threshing and harvesting grain, John was a model maker in the 1860’s when a model of an invention was required to obtain a design patent. It started with his knowledge and experience in “improving mechanical movements” related to converting up and down movement into rotary motion. This, coupled with a desire to be more efficient in cutting out wood for making models that lead to this initial scroll saw. From there, Barnes used this methodology as a stepping stone to produce many other types of foot powered machinery such as lathes and table saws.

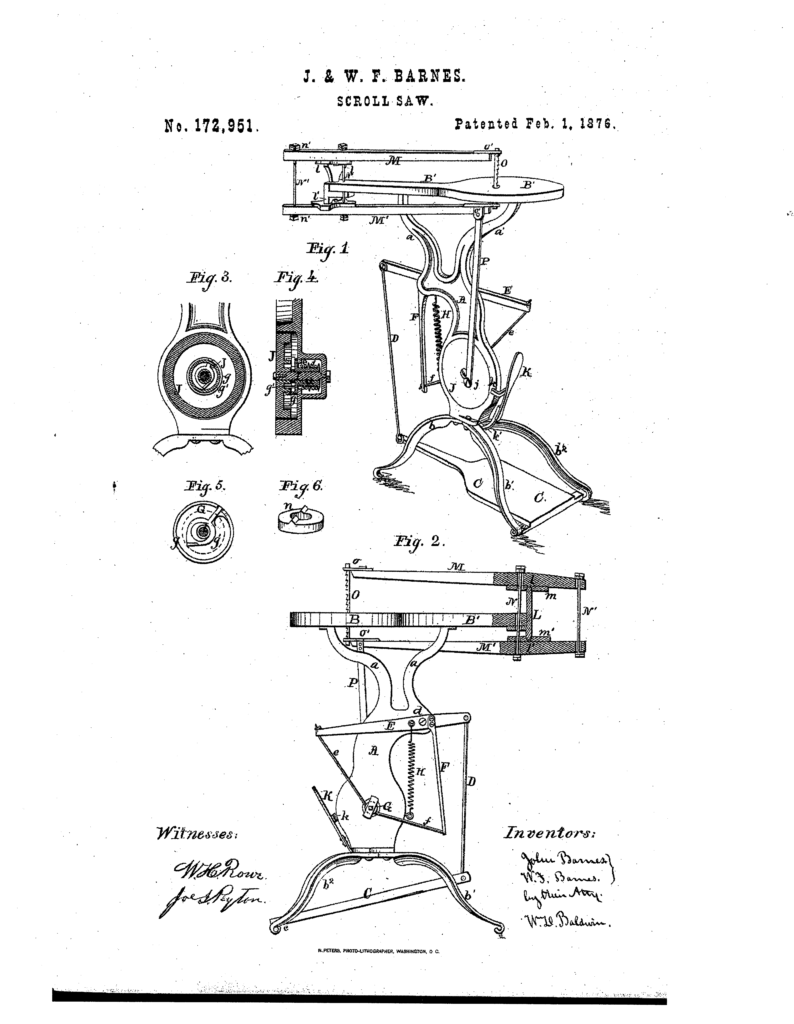

The initial patent John and his brother, William Franklin (W. F.) Barnes obtained, #172,951 on February 1, 1876, was, as even they described it, a crude looking saw. In looking at the patent drawing and description, the key part was the device that converted the up and down motion of the treadle into rotary motion that then drove a pitman arm up and down to move the saw blade. This appears to be based on an earlier patent, # 114,514, Improvement in Mechanical Movements. Essentially what is known today as a “ratchet and pawl mechanism.” It resulted in disconnecting the treadle from the rest of the machine except on downward motion thus eliminating the need of the operator to keep in step with the location of the treadle.

One would assume the Barnes brothers fine-tuned the design as John likely was using the saw as it was refined to cut out wooden parts for the models he made all the while thinking about what it might take to manufacturer the machine. Nothing like necessity being the father of an invention!!

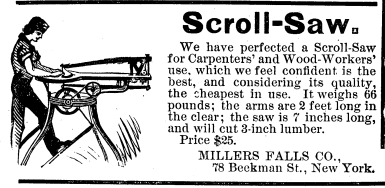

Advertising back then was word of mouth as well as notices in Scientific American and various trade journals like Manufacturer and Builder. The earliest such “ad” I am aware of is dated November, 1875.

Interesting in that it is from the Miller Falls Company and not W. F. and John Barnes. The sketch looks like the machine in the first Barnes catalog I am aware of dated May, 1877 and still used up until 1885.

Millers Falls did offer a number of foot powered scroll saws beginning with a Lester in 1878 which was a much smaller amateur/hobby grade machine. While this ad has been used as a basis for saying Millers Falls invented this saw, think by all other measures, they were just an early agent or reseller of the saw as that is the only mention of it by Miller Falls that I am aware. In addition, Millers Falls they did not make any commercial grade foot powered machinery even though they manufactured a very large number and several types of amateur/hobby grade foot powered machines. Such reselling of machines was common back then and would have resulted in helping Barnes get publicity. I would image, however, with the capabilities of the saw and improvement in productivity of those using the machines (see testimonials below), it would not take long for the #7 to be in demand by builders and carpenters thus the transition of selling them themselves.

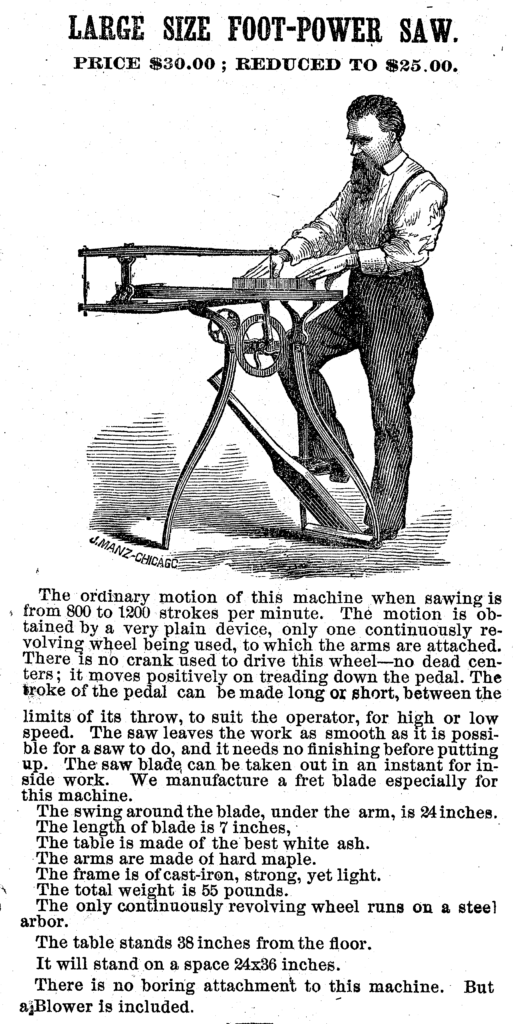

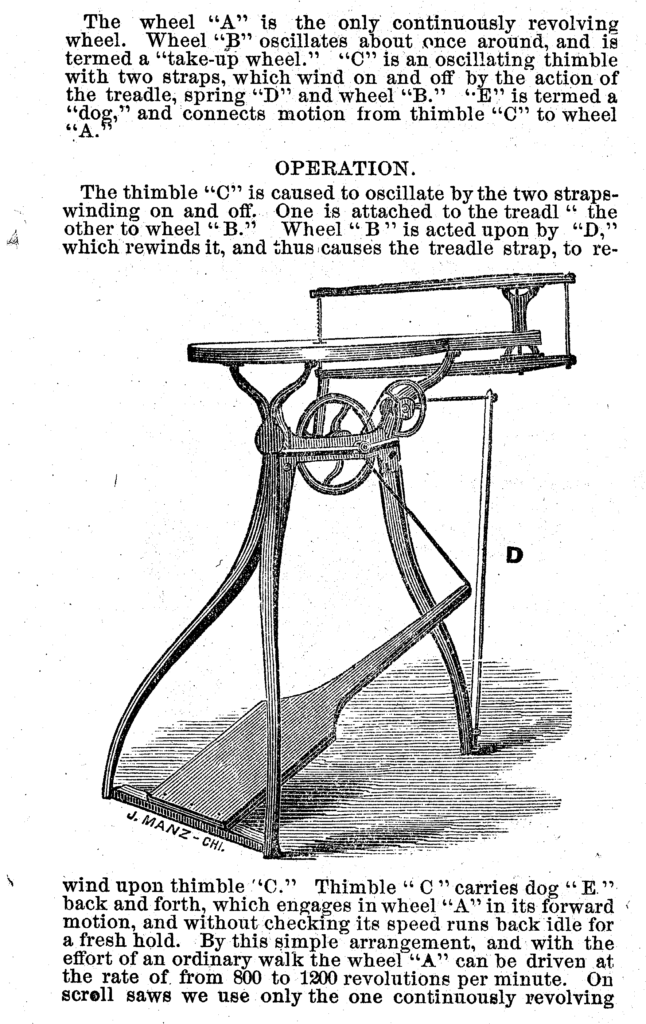

Here is an illustration from an early Scientific American that is thought be about that same time frame.

Being the first model, the #7 went through a number of changes over its life span where more than 14,000 were made. These changes came from Barnes continued drive to improve the capability of their products. However, the core capabilities of the machine, 24 inch throat and 7 inch pinned blade, did not change over the entire time.

The earliest catalog produced by Barnes that I am aware of is dated May 1877. In it is this listing for the Barnes #7 in what can be called the real first production version. It used a wooden return spring and had the three leg designed they used for the all of the rest of the production. Here is that catalog illustration. Note the lack of the wooden return spring in this first illustration. Since the second illustration is in that same catalog and just a page before this, think it is safe to say that the artist just left it off and this was not some type of “design change.”

These very early machines had a table made of ash and not hard maple as the rest of the #7’s and most of the other Barnes machines. Barnes did give these machines serial numbers which are found stamped into the front end of the table (nearest to the operator.) at least one example of this early type has the serial number stenciled in big numbers on the underside of the table. Some early machines don’t seem to have any sign of a serial number.

In that catalog, they went into a lot of detail to explain how all that worked together as below.

After this initial version using the wooden return spring, Barnes switched to a cast iron arm with a pulley at the end and a coil spring as the return mechanism about 1885. This likely came from they fact that the wooden return arm became bent from usage and under some tension even when the saw was not in use. Observations of machines that use the wooden arm typically show what appears to be a replacement wood arm or one that has been reinforced with a metal strip and still are curved back toward the operator.

Here is a closeup of this cast iron return arm on a round belt #7.

The final design, called the “Improved #7”, kept the cast iron return arm with the spring but switch from the round belt to their patented belt with holes that they called “belt gearing.” Belt gearing was a significant improvement from round belting as it virtually eliminated slipping that resulted primarily when only part of a pulley was in contact with the belting – big wheel driving a much smaller wheel. However, the design of the #7 did not result in this so the round belt #7’s work just about as good as the flat belt gearing in the Improved #7. Some users actually prefer the round belt version to the flat belt version!!